IntroductIon

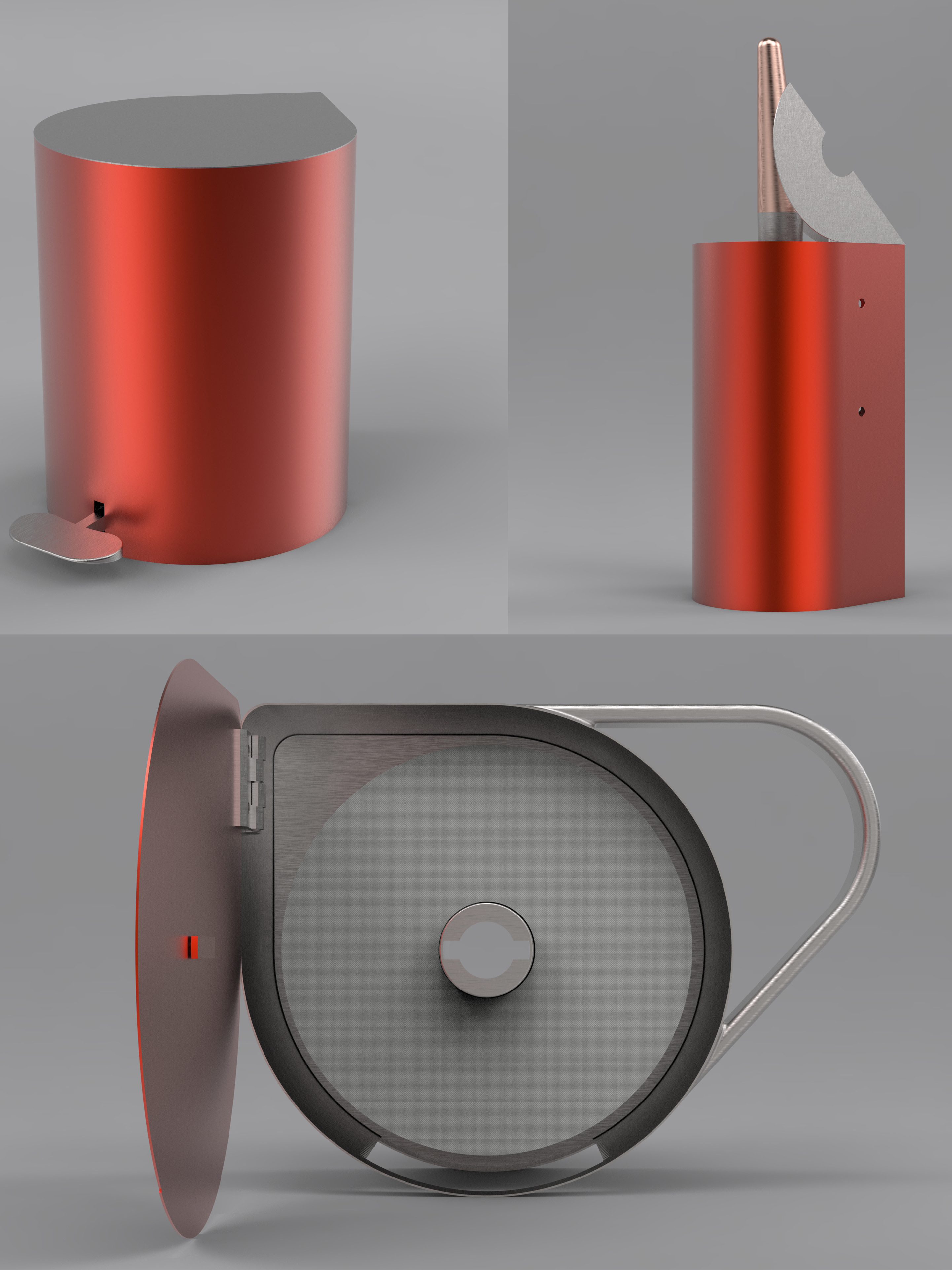

Project Brief: For this project, I was asked to design a specific kitchen utensil with a well-defined use function, a garlic press (also referred to as a garlic crusher). It is a hand-held and manual utensil operated with human power and an alternative to cutting or mincing the garlic with a knife.

The DesIgn

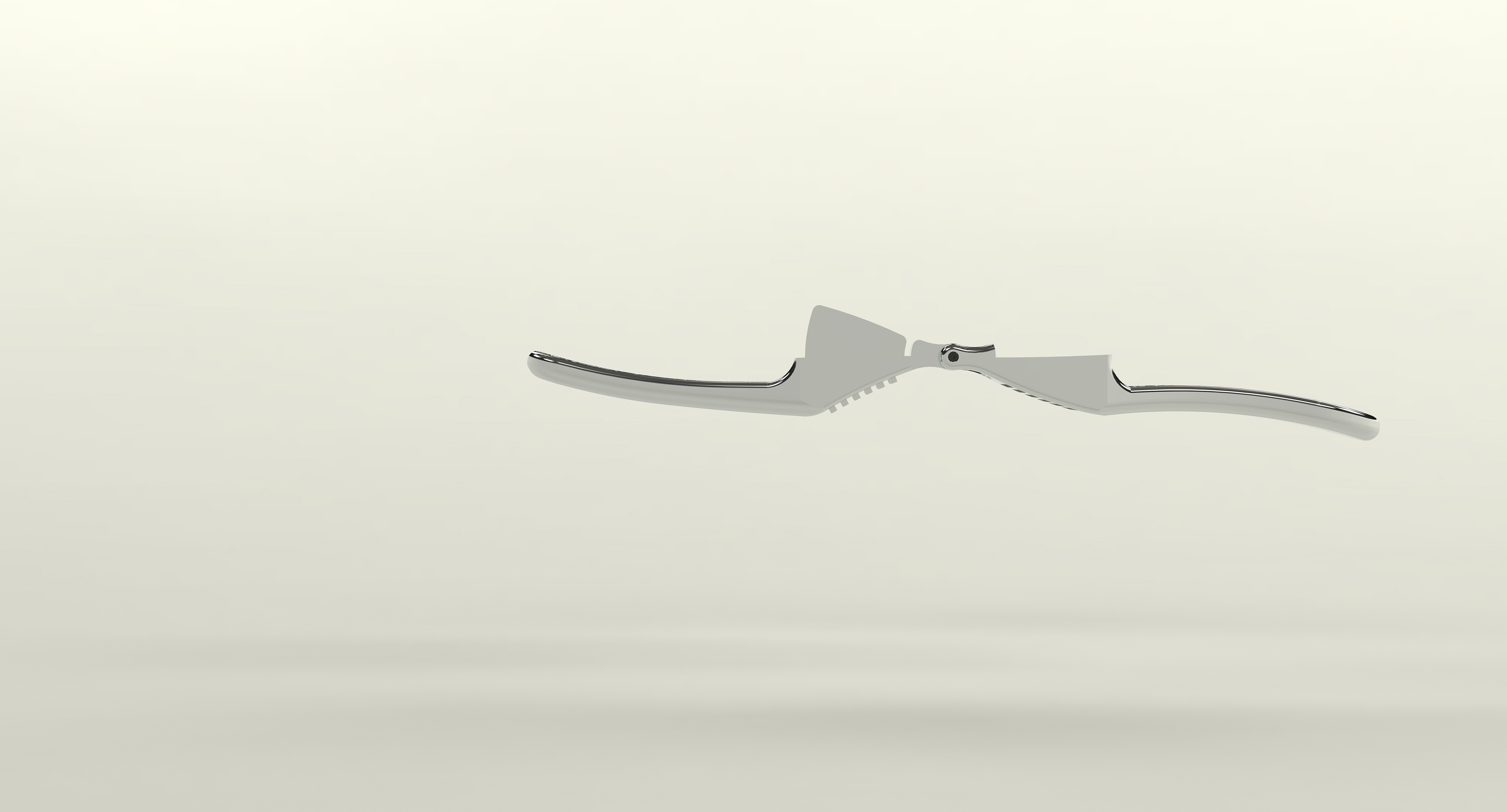

"I decided to go with an aluminum crusher design. The main points I focused on were the ease of cleaning, crushing efficiency, and durability. "

DesIgn Process

This being a handheld physical product, I made my first "sketch" using air-dry clay. Later I reinforced the model with a 3D printed spine to test the grip.

Prototypes

After clay modeling I started to model in CAD this first prototype was made to test my motion study which it passed. But it failed to crush the garlic (the metal pin gave away) and the handle was uncomfortable.

In the second prototype I redesigned the front half to change the weak pin to a stronger screw. Also the sieve geometry was had a complete overhaul with a mathing surface.

This prototype's sieve was broken while being tested and the matching surface made the press impossible to clean.

The third version had minor upgrades. A replacable sieve and cleaner to test different tolerences of matching surfaces made the press easier to clean, but it was still impractical. Also the hinge gave away because of the new tolerances.

In the last prototype, I reduced the sieve hole count and used a single surface for crushing. With the new tolerances the new press held up to extensive torture testing. Both the crushing surface and the sieve was easy to clean and it was pretty effective.